The EPA vs. American Mining Congress case in the early 90s resulted in the "remanded smelter slag" rule. The mining industry convinced the court, and even EPA, that treating slag piles as "waste" with 365 day storage ("speculative accumulation") under RCRA statute, did more harm than good. Today, it's an industrial mineral, and can be kept under basically the same conditions as mined angelsite or other leaded silicate, because treating it otherwise is anti-recycling.

Anti-recycling means that the identical chemical solid is governed more strictly if it's recovered from waste instead of mined from the ground.

The slag has residual mineral value which is used at peak periods of demand. In industrial mineral trade, "peak periods of demand" occur over decades, not months. Had EPA won, all the slag would be covered and capped, and perhaps never dug up again. Meanwhile the mines would be extracting raw ores of various grades, and utilizing high grades or low grades not based on the date they were mined, but on the economy for the material.

The Wall Street Journal has a story with an example of how different grades of mined iron material have different demand.

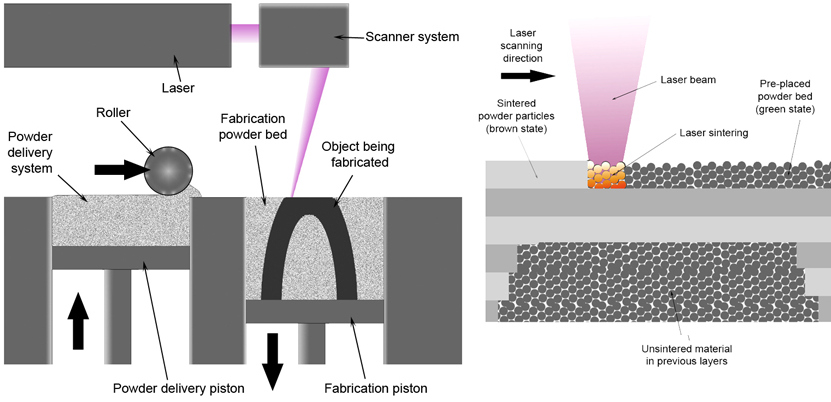

"The lump premium, the extra paid for lump-form iron ore, is falling, notes Morgan Stanley. The standard product, fines, requires compacting into lumps or pellets before going into blast furnaces. That process, known as sintering, is a dirty business." -Helen Thomas, WSJ "Is this a Tell..."It's rare in recycling circles to talk about sintering. That's basically a hot and somewhat nasty way of taking "fines" from iron ore dust and getting them into a form where they can smelt more easily. "Lump form" iron doesn't need to be sintered, and is considered "high grade". Powder metallurgy is a whole different business than smelting at industrial scale.

And this applies to virgin leaded silicate... mined pieces which are the best size for smelting are worth more than dust or huge pieces that need to be broken.

It is the size of the CRT cullet pieces, the contamination (e.g. from higher melting point barium), the percent of lead (and demand for that lead) that matters to engineers. The engineers don't like "fines", they don't like CRT glass that's been shredded and needs to be sintered.

But today's biggest problem, for CRT glass, is anti-recycling... treating identical secondary material at spec more harshly if it's recovered from waste. Today's problem selling CRT glass is less about the engineers - its about the environmental lawyers. And they don't like liability... and our "e-waste" industry is shoveling that at them as fast as we can.

| How to make powder and fines in CRT glass into furnace ready cullet |

Metal dust isn't worthless. But properly sized cullet is more valuable. When steel prices are high, lump form iron is expensive, and sintering goes on 24/7. And when lead ore prices are at peak on the London Metals Exchange (LME), slag piles from copper and lead mines, which have a decent percentage of lead Pb in the silica, are treated as mined material and bought and sold as a beveling agent, fluxing agent, etc. And pummeled and shredded CRT glass can be sintered and recycled... it's just a lot less economical.

|

| Less than $1 Worth of Paper |

Dusty material which is too fine "blows" out the smelter and increases plant cleanup costs, so a 2" piece of silica with 5% lead has more value than a 15% lead silica that is pummelled to powder (until it is sintered).

E-Stewards made an announcement this week about the Kuusakoski "box in a landfill" storage proposal. The automated machinery at Kuusakoski may tend to produce a lot more fines than a hand disassembly or "CRT Angel" process. It's more expensive to sell CRT glass that's broken into too small of pieces, that is a longer wait for the LME breakeven price, and so the glass is worth less. So, the idea is that you put the glass all in one place, say in barrels or cells, in a landfill. So, it's speculatively available, but also discarded... a way around "speculative storage". I'm not totally against this, but the economics are not about "glass", they are about the form the glass winds up in when you skimp on labor and wind up with mixed cullet and fines.

When E-Stewards says that land application of CRT glass is a "last resort", they aren't addressing the question of why some processes have more "last resorts" than others. This is recycling 101 - lousy grading, lousy quality, gets dumped first when prices are bad. And the people who can't make the quality spec always blame "the markets".

EPA Policy people need to understand is that the current market glut is not one, but two self-inflicted wounds. In part, it's the percentage of fine glass when operations try to reduce labor by running CRTs through shredders. But it's also "anti-recycling", a bias loop against secondary materials, which has turned the buyers off.

The smelters I spoke with were all willing to take CRT glass if it was properly sized (or if not, to charge fees for sintering), i.e. it was turned into a product they buy - fluxing agent. But they were NOT willing, under any circumstance, to lose the precedent set in the early 90s, by the remanded smelter waste rule, that would put a 365 day "speculative accumulation" time clock on their raw materials. Sell them a commodity and they will buy it. Ask them to file as a waste processor, and even if the material is twice as rich as ore fines, they will tell you to go pound sand.

Translated roughly, for jist, from Spanish:

"Robin, we've read the reports from Xstrata and Noranda, and your samples are good. We can do this. But it's a favor, not a business. This smelter generates $55 million dollars per day. If we have to walk down the hall to the environmental lawyers office, your material is not worth it at any price. We did this to help our neighbors, the people in the village you were trying to help. We didn't do this to get into the waste business."And they are right, because in the E-Stewards press release, BAN stated this week:

"Use of CRT glass as an alternative fluxing agent in lead smelters will remain a preferred option as long as a lead recovery rate of 95% or higher can be demonstrated by the smelter. In the absence of such data, this option will be considered as a Conditionally Allowable Option only."That sounds like a lot of monitoring and a lot of trips to the smelter legal office. Because BAN doesn't understand industrial minerals. Virgin slag does not involve recovery of 95% or higher. But if the lead ISN'T in the slag, the smelter has to mine lead and add it to the flux.

It is a bit like banning use of recycled paper in toilet paper because the paper is lost after it's used. So we should cut down spotted owl houses to make toilet paper, because it's not good enough a fate for our recycled office paper...? If it replaces mined / extracted material, it is recycling. Period.

| Size Matters: How big is your broken glass? |

Copper smelters today are all adding virgin lead to silica. They are looking at size of nuggets as well as lead chemistry (and the negative value of barium panel glass on melting points). And when the LME is high, they will go out to the places where the remanded smelter slag is piled, and they will recycle the fluxing agent when the time is right. Not in 365 days.

Their lawyer said that if there is any CRT glass in the slag pile, the entire pile could be subject to 365 days "speculative accumulation". He warned the engineers to stay away from it. Four people in an NGO could vote a different way tomorrow, he said, exposing the company to enormous liability.

Anti-Recycling is the kind of stupid environmentalism that I thought we transitioned from in the 1980s and 90s (yes, I do remember people making the anti-toilet-paper argument at Massachusetts DEP, that it was "downcycling" compared to greeting cards... which are often not even sold or opened or read).

"If I was the richest man in Mexico, and every day I drove bought a cup of coffee, I might see your add for Fair Trade Coffee, and maybe I'd try it. Maybe I'd even pay a bit more for it. But if I had to sign a paper pledging I was good enough a person to drink your coffee... well good luck selling that."Wendy Neu is on the BAN board. She voted right on the Kuusakoski exemption. But she doesn't seem to understand sintering or fluxing agent, and the decision by E-Stewards continues to poison the well on CRT glass as an industrial mineral.

No comments:

Post a Comment